ODP is a measure of how much a refrigerant depletes the ozone layer in the stratosphere over a specific time period, usually 100 years, compared to chlorofluorocarbon-11 (CFC-11), which has an ODP of 1. The higher the ODP, the more the refrigerant depletes the ozone layer. The refrigerant that has the highest ODP is halon-1301, which has an ODP of 10.

What is ODP and Why Does It Matter?

ODP is a relative scale that compares the amount of ozone destroyed by a unit mass of a refrigerant to the amount of ozone destroyed by a unit mass of CFC-11 over a given time period. For example, if a refrigerant has an ODP of 0.5, it means that one kilogram of that refrigerant will destroy 0.5 kilograms of ozone over 100 years.

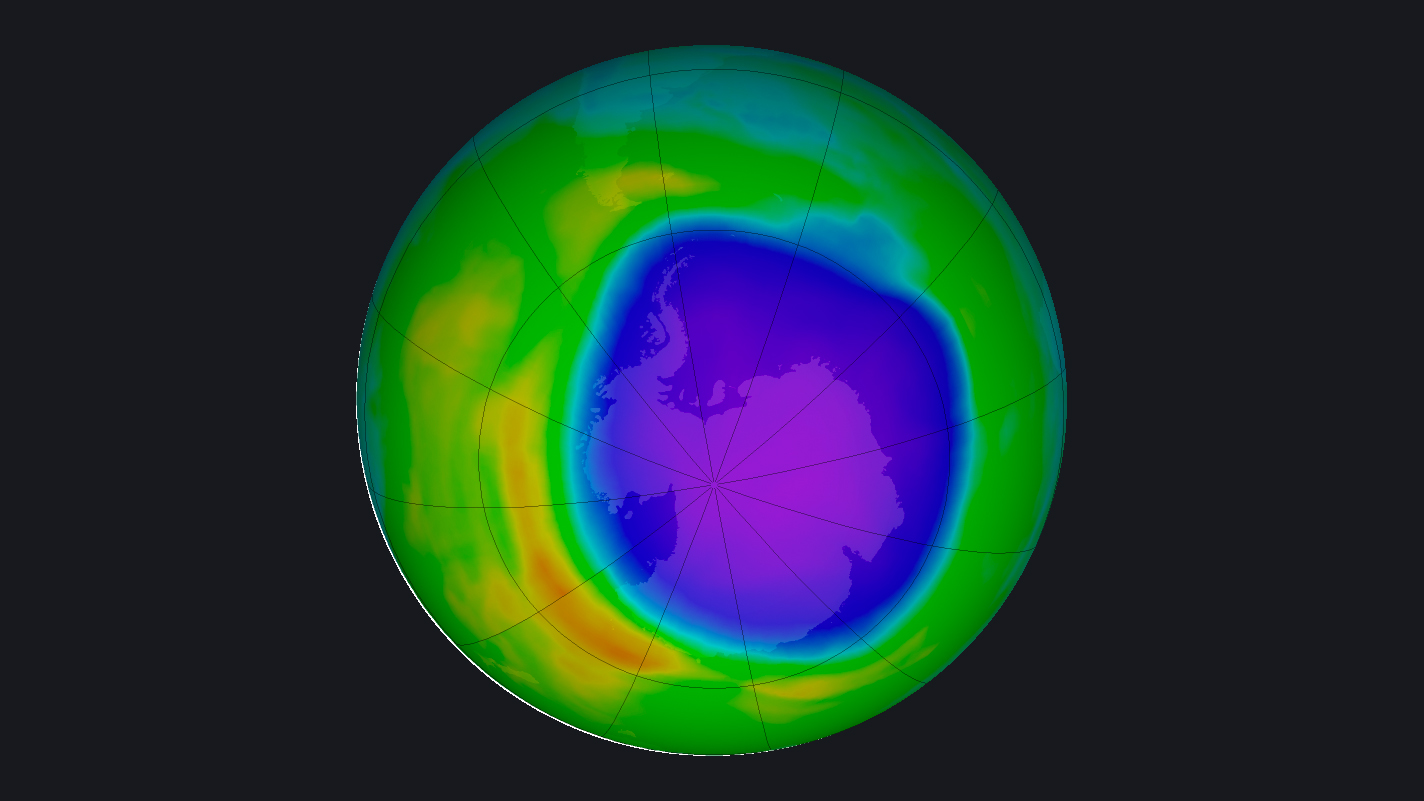

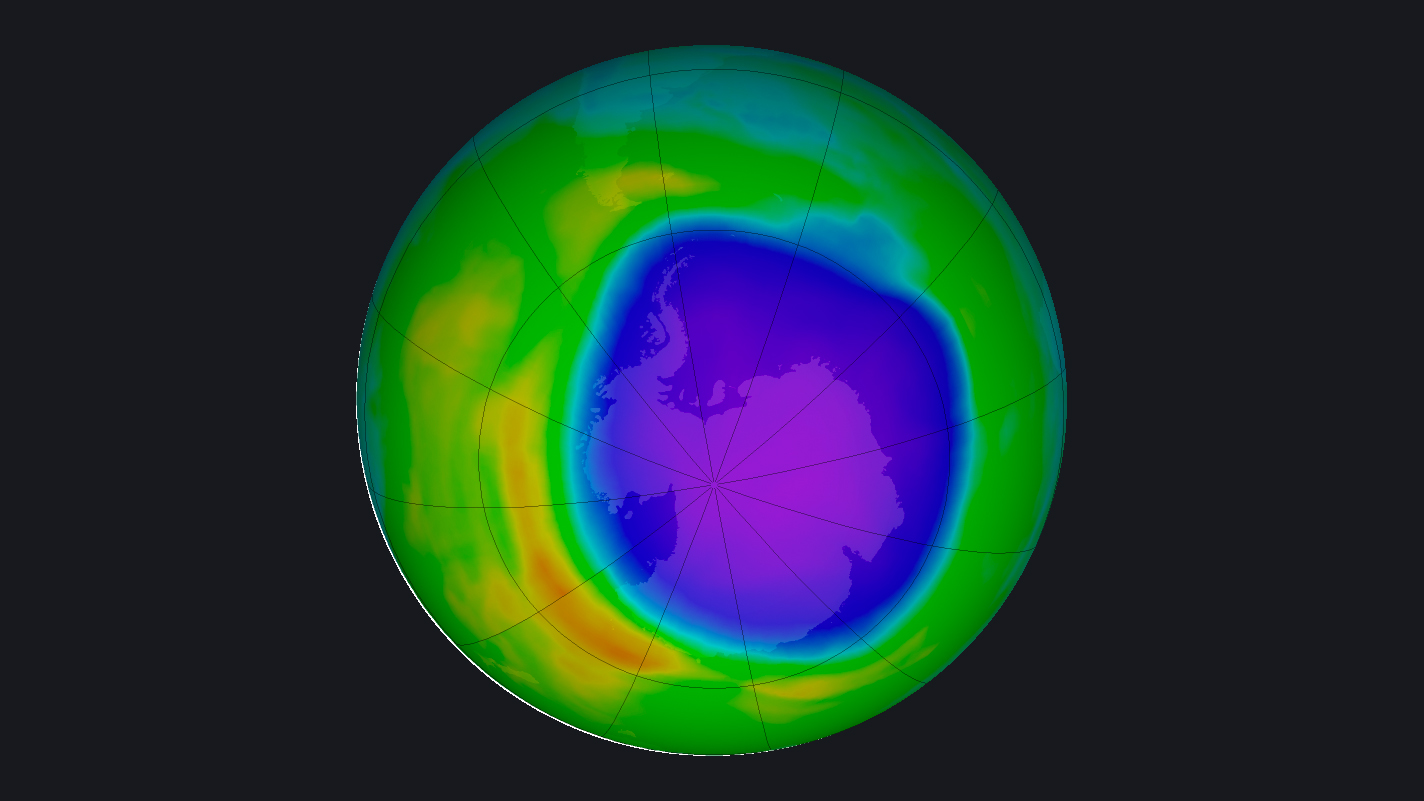

ODP matters because it reflects the impact of refrigerant emissions on the ozone layer. The ozone layer is a thin layer of gas in the stratosphere that protects the earth from harmful ultraviolet (UV) radiation from the sun. UV radiation can cause skin cancer, eye damage, immune system suppression, and crop damage.

Refrigerants can leak from cooling systems due to improper installation, maintenance, or disposal. When they reach the stratosphere, they can react with ozone molecules and break them down into oxygen molecules. This reduces the amount of ozone in the stratosphere and creates a hole in the ozone layer.

The higher the ODP of a refrigerant, the more it depletes the ozone layer and the more it affects the earth’s health. Therefore, it is important to use refrigerants with low ODP values and to prevent or minimize refrigerant leaks.

How to Choose a Low-ODP Refrigerant?

How to Choose a Low-ODP Refrigerant?

Choosing a low-ODP refrigerant is not only good for the ozone layer, but also for your cooling system and your wallet. Low-ODP refrigerants can offer better performance, efficiency, and reliability than high-ODP refrigerants. They can also help you comply with current and future regulations that aim to phase out or phase down high-ODP refrigerants.

However, choosing a low-ODP refrigerant is not as simple as picking the one with the lowest ODP value. You also need to consider other factors, such as:

- Global warming potential (GWP): GWP is a measure of how much a refrigerant contributes to global warming over a specific time period, usually 100 years, compared to carbon dioxide (CO2), which has a GWP of 1. The lower the GWP, the less the refrigerant contributes to global warming. You need to choose a refrigerant that has both low ODP and low GWP values.

- Safety: Refrigerants can have different safety classifications based on their toxicity and flammability. Some low-ODP refrigerants are non-toxic or have low toxicity (Class A), while others have high toxicity (Class B). Some low-ODP refrigerants are non-flammable (Class 1), while others are flammable or mildly flammable (Class 2 or Class 2L). You need to choose a refrigerant that matches your safety requirements and standards.

- Compatibility: Refrigerants can have different compatibility with your cooling system components and materials, such as seals, valves, hoses, compressors, etc. You need to choose a refrigerant that is compatible with your existing or new equipment and does not cause corrosion, leakage, or damage.

- Availability: Refrigerants can have different availability in your region or market, depending on their supply and demand. You need to choose a refrigerant that is readily available and affordable for your cooling system needs.

To help you choose a low-ODP refrigerant, you can consult with your cooling system manufacturer or service provider. They can recommend you the best low-ODP refrigerant for your specific application and equipment.

What are Some Examples of Low-ODP Refrigerants?

There are many low-ODP refrigerants available in the market today. Some of them are natural refrigerants, such as ammonia (R-717), carbon dioxide (R-744), hydrocarbons (propane R-290, iso-butane R-600a, etc.), water (R-718), air (R-729), etc. These refrigerants have very low or zero ODP values and are environmentally friendly. However, they may also have some drawbacks, such as flammability, toxicity, high pressure, low efficiency, etc.

Other low-ODP refrigerants are synthetic or man-made refrigerants, such as hydrofluorocarbons (HFCs), hydrofluoroolefins (HFOs), or blends of HFCs and HFOs. These refrigerants have low or very low ODP values and are designed to replace high-ODP refrigerants such as chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs). However, they may also have some drawbacks, such as flammability, mild toxicity, high cost, high GWP, etc.

Here are some examples of low-ODP refrigerants:

- R-717 (ammonia): This is a natural refrigerant that has an ODP of 0 and a GWP of 0. It is widely used in industrial and commercial refrigeration applications, such as cold storage, ice rinks, food processing, etc. It has excellent thermodynamic properties and high efficiency. However, it is also highly toxic and flammable, and requires special safety precautions and equipment.

- R-744 (carbon dioxide): This is a natural refrigerant that has an ODP of 0 and a GWP of 1. It is used in various applications, such as supermarket refrigeration, heat pumps, mobile air conditioning, etc. It has good environmental and safety characteristics and low cost. However, it also operates at very high pressures and requires high-quality components and materials.

- R-290 (propane): This is a natural refrigerant that has an ODP of 0 and a GWP of 3. It is used in small-scale applications, such as domestic refrigerators, freezers, air conditioners, etc. It has good performance and efficiency and low cost. However, it is also highly flammable and requires strict safety measures and standards.

- R-1234yf: This is a synthetic refrigerant that has an ODP of 0 and a GWP of 4. It is used in automotive air conditioning systems and some chillers. It has similar properties and performance to R-134a, which it is intended to replace. However, it is also mildly flammable and more expensive than R-134a.

- R-1234ze (E): This is a synthetic refrigerant that has an ODP of 0 and a GWP of 7. It is used in chillers, heat pumps, and some refrigeration applications. It has similar properties and performance to R-134a, which it is intended to replace. However, it is also mildly flammable and more expensive than R-134a.

- R-32: This is a synthetic refrigerant that has an ODP of 0 and a GWP of 675. It is used in air conditioners and heat pumps. It has better performance and efficiency than R-410A, which it is intended to replace. However, it is also mildly flammable and requires special handling and equipment.

Conclusion

Refrigerant is a substance that is used to transfer heat in cooling systems. Refrigerant can have different ozone depletion potential (ODP) values, which measure how much they deplete the ozone layer in the stratosphere over a specific time period compared to CFC-11. The higher the ODP, the more the refrigerant depletes the ozone layer.

The refrigerant that has the highest ODP is halon-1301, which has an ODP of 10. However, choosing a low-ODP refrigerant is not as simple as picking the one with the lowest ODP value. You also need to consider other factors, such as GWP, safety, compatibility, availability, etc.

To choose a low-ODP refrigerant for your cooling system, you can consult with your cooling system manufacturer or service provider. They can recommend you the best low-ODP refrigerant for your specific application and equipment.

How to Choose a Low-ODP Refrigerant?

How to Choose a Low-ODP Refrigerant?